DSLHG Series Multipurpose Valves

The multipurpose control valve that offers regenerative circuits, directional control, flow control, counterbalance and reduced shock features.

DSPC – DSPG Series Shut-Off Solenoid Operated

The shut-off type solenoid operated directional valves are poppet type solenoid operated two-way directional valves developed to meet the needs of this age such as energy and resources saving.

Dual Check Valves PDCV

Description

Series PDCV-08 pilot-operated check valves lock a cylinder in any rest position. They are intended for direct mounting in the cylinder as weel as for mounting in a manifold block or a line mounting body.

EDFG-01 Shockless Type Directional and Flow Control Valves

These valves are well accepted by industrial users as shifting time adjustable type shockless valves. By employing the basic design concept of the “G series solenoid operated directional valves”, we have been successful developing the shifting time adjustable shockless valves with high performance which makes the speed setting possible at any high speed operation. In combination with the newly developed digital amplifiers, the further enhancement of maneuverability and repeatability of the valves can be realized.

EDG Pilot Relief Valves

This valve consists of a small DC solenoid and a direct-acting relief valve. It serves as a pilot valve for a low flow rate hydraulic system or a proportional electro-hydraulic control valve and controls the pressure in proportion to the input current. Note that this valve is used in conjunction with the applicable power amplifier.

EH Pilot Relief Valves (EHDG-01)

The valve can be used as a pilot valve of the Proportional Electro- Hydraulic Control Valves. The valve can also be used as a relief valve for the hydraulic system where a small flow rate and continuous pressure control are required.

EH Pilot Relief Valves (EHDG-01)

The valve can be used as a pilot valve of the Proportional Electro- Hydraulic Control Valves. The valve can also be used as a relief valve for the hydraulic system where a small flow rate and continuous pressure control are required.

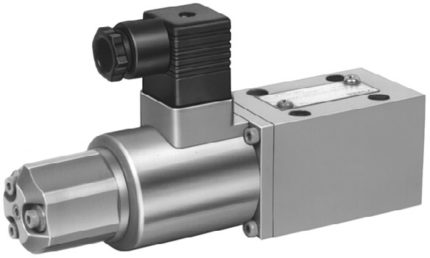

EHDFG 01/03 Proportional Directional and Flow Control Valves

These valves incorporate two control functions – flow and direction – which simplify the hydraulic circuit composition and therefore the cost of the system is reduced.

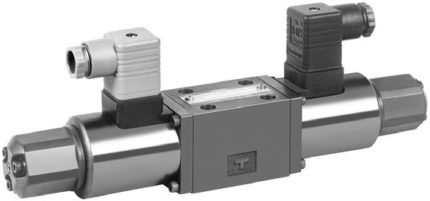

ELDFG High Speed Proportional Directional & Flow Control with On Board Electronics

Closed loop, high response type proportional electro-hydraulic directional and flow control valves with on board electronics. Two direct type models with a maximum rated flow rate up to 80 l/min (@.ΔP=1MPa) are available. Two different available models of two stage OBE valves have a maximum rated flow rate up to 500 L/min (ΔP=0.5MPa (72 psi) at each port).

Excavator Pipe Rupture Valve CFS

Description

The excavator pipe rupture valve is used wherever so required by the standards ISO 8643, EN 474 and DIN 24093 for excavators with a lifting device (e.g. a load hook on the bucket). The actuators concerned are the lift cylinder, the stick cylinder and the adjusting cylinder. The valve should also be used on machines in which a pipe rupture on the actuators could produce dangerous situations (e.g. machines for materials handling and demolition).

The excavator pipe rupture valve, series CFS (Compact Flow Control and Safety Valve), prevents uncontrolled lowering of the actuator in the event of a pipe or hose rupture. In addition, the CFS valve holds the actuator in its position when the main valve is centred. The valve also includes a secondary pressure-relief function, which protects the actuator against overload. The inlet and actuator ports on the CFS are standard SAE flanged ports, and the valve can therefore be retrofitted to existing equipment without any difficulty.

Excavator Pipe Rupture Valve CFS

Description

The excavator pipe rupture valve is used wherever so required by the standards ISO 8643, EN 474 and DIN 24093 for excavators with a lifting device (e.g. a load hook on the bucket). The actuators concerned are the lift cylinder, the stick cylinder and the adjusting cylinder. The valve should also be used on machines in which a pipe rupture on the actuators could produce dangerous situations (e.g. machines for materials handling and demolition).

The excavator pipe rupture valve, series CFS (Compact Flow Control and Safety Valve), prevents uncontrolled lowering of the actuator in the event of a pipe or hose rupture. In addition, the CFS valve holds the actuator in its position when the main valve is centred. The valve also includes a secondary pressure-relief function, which protects the actuator against overload. The inlet and actuator ports on the CFS are standard SAE flanged ports, and the valve can therefore be retrofitted to existing equipment without any difficulty.

Excavator Pipe Rupture Valve ESV

Description

Excavator pipe rupture valves prevent uncontrolled cylinder movement in the event that a pipe or hose bursts. The ESV valve fulfills all of the requirements of the ISO 8643 and EN 474-5 standards for excavators.