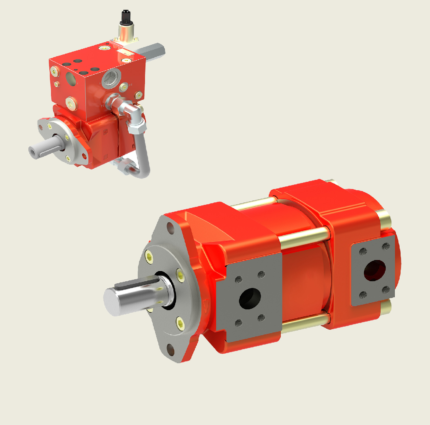

External Gear Pumps, Series AP

-

Description

The product range of Bucher Hydraulics includes single pumps 05-100-212-212HP-250HP-312HP (corresponding with the common group denominations: 05-1-2-2.5-3) and several combinations of double pumps, triple pumps, and so on, that can be assembled together according to versions of displacement, flanging, and auxiliary valves.

Advantages

- High overall efficiency thanks to optimised hydraulic compensation

- Design and materials that guarantee excellent technical specifications and long life service

- Optimum quality/price ratio

- Customised models can be built for specific applications:

- Dedicated front covers to improve mechanical and life performances in case of radial/axial loads

- Dedicated back covers with integrated circuits to control pressure and flow.

Technical Data

Ordering Code Material Displacement

cm³/revOperating pressure up to

barPeak pressure

barMin. speed

rpmSpeed max.

rpmAP/APR05 Aluminium 0.25 – 1.6 190 230 500 7000 AP100 Aluminium 1.2 – 10.0 210 280 500 5000 AP/APR212 Aluminium 4.4 – 27.1 250 300 500 4000 AP/APR212HP Cast iron 15.1 – 34.1 250 300 500 3500 AP250HP Cast iron 15.2 – 54.0 300 320 500 3500 AP312HP Cast iron 40 – 75 300 320 500 3000 Downloads

Models

- Single pumps, unidirectional

- Single pumps, reversible

- Aluminium and cast iron versions

- Double and triple pumps, unidirectional, in several configurations.

- With integral flow or pressure control valve .

- With outrigger bearing for axial and radial loads.

Applications

- Tractors

- Agricultural machines

- Earth moving machines

- Lift trucks

- Construction machinery

- Front loaders

- Sweepers

- Hydraulic hoists

External Gears Pumps, Series AP

Description

The product range of Bucher Hydraulics includes single pumps 05-100-212-212HP-250HP-312HP (corresponding with the common group denominations: 05-1-2-2.5-3) and several combinations of double pumps, triple pumps, and so on, that can be assembled together according to versions of displacement, flanging, and auxiliary valves.

Advantages

- High overall efficiency thanks to optimised hydraulic compensation

- Design and materials that guarantee excellent technical specifications and long life service

- Optimum quality/price ratio

- Customised models can be built for specific applications:

- Dedicated front covers to improve mechanical and life performances in case of radial/axial loads

- Dedicated back covers with integrated circuits to control pressure and flow.

Technical Data

| Ordering Code | Material | Displacement cm³/rev |

Operating pressure up to bar |

Peak pressure bar |

Min. speed rpm |

Speed max. rpm |

|---|---|---|---|---|---|---|

| AP/APR05 | Aluminium | 0.25 – 1.6 | 190 | 230 | 500 | 7000 |

| AP100 | Aluminium | 1.2 – 10.0 | 210 | 280 | 500 | 5000 |

| AP/APR212 | Aluminium | 4.4 – 27.1 | 250 | 300 | 500 | 4000 |

| AP/APR212HP | Cast iron | 15.1 – 34.1 | 250 | 300 | 500 | 3500 |

| AP250HP | Cast iron | 15.2 – 54.0 | 300 | 320 | 500 | 3500 |

| AP312HP | Cast iron | 40 – 75 | 300 | 320 | 500 | 3000 |

Downloads

Models

- Single pumps, unidirectional

- Single pumps, reversible

- Aluminium and cast iron versions

- Double and triple pumps, unidirectional, in several configurations.

- With integral flow or pressure control valve .

- With outrigger bearing for axial and radial loads.

Applications

- Tractors

- Agricultural machines

- Earth moving machines

- Lift trucks

- Construction machinery

- Front loaders

- Sweepers

- Hydraulic hoists

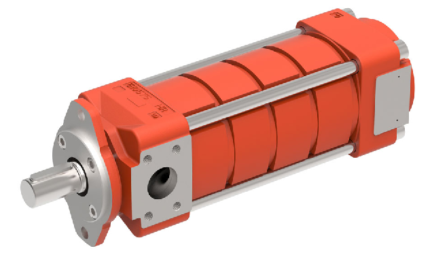

QXEH Internal Gear Pumps

Description

Highly dynamic variable-speed pump operation

The QXEH series has been specially developed for pumping duties in highly dynamic servo drives with a reversing function. Using the pinion-shaft technology, high pressures up to 280 bar are developed in a single stage. QXEH pumps are therefore particularly well suited for a wide range of applications in industrial hydraulics where there are high demands on power density, energy efficiency and machine productivity. At the same time, they ensure maximum operational reliability coupled with minimal flow- and pressure-pulsations even during operation with highly dynamic load cycles.

Advantages

- Open circuits up to 280 bar max. working pressure

- Specially for highly dynamic drives with a reversing function

- Extremely low noise levels < 75 dB(A)

- Can be combined to make a double pump

- Can be used with almost all hydraulic fluids

- Can be used with fixed- and variable-speed drives

Technical Data

| Type | Operating pressure (continuous) up to bar |

Operating pressure (intermittend) up to bar |

Displacement cm³/rev |

Speed max. rpm |

|---|---|---|---|---|

| QXEH32 | 250 | 280 | 10-16 | 5500 |

| QXEH42 | 250 | 280 | 20-32 | 4000 |

| QXEH52 | 250 | 280 | 40-63 | 3200 |

| QXEH62 | 250 | 280 | 80-125 | 2700 |

| QXEH82 | 250 | 280 | 160-250 | 1900 |

Applications

- Hydraulic presses

- Injection moulding machines

- Machine tools

- Waste compactors

- Lift/elevator drives

- Pressure diecasting machines

- Plastics-processing machines

- Hydraulic power units

Options / Accessories

- Bolt-on valves

- Pipe flanges

QXM Internal Gear Units

Description

Pump/motor operation in multi-quadrant applications

The QXM series is an extension of the QX pump series and is suitable for operation as both a pump and a motor. Thanks to the completely symmetrical design, these units can be used in multi-quadrant operation and are suitable for a wide range of applications in both industrial and mobile hydraulics. In 4-quadrant operation, the movement of cylinders can be controlled on the one hand, and exploited to recover/save energy on the other. For example, if the unit works as a pump during a lifting process, it can then work as a motor during the lowering process to feed energy back into the system.

Advantages

- Open/closed circuits up to 400 bar max. working pressure

- Low noise level < 75 dB(A)

- Particularly suitable for multi-quadrant operation

- Can be used with all hydraulic fluids

- Can be used with fixed- and variable-speed drives

Technical Data

| Type | Operating pressure (intermittend) up to bar |

Operating pressure (continuous) up to bar |

Displacement cm³/rev |

Speed max. pump rpm |

Speed max. motor rpm |

|---|---|---|---|---|---|

| QXM2 | 400 | 100-320 | 5-16 | 4000 | 4600 |

| QXM3 | 400 | 100-320 | 10-32 | 3200 | 4250 |

| QXM4 | 400 | 100-320 | 20-63 | 2900 | 3900 |

| QXM5 | 400 | 100-320 | 40-125 | 2500 | 3500 |

| QXM6 | 400 | 100-320 | 80-250 | 2250 | 3600 |

| QXM8 | 400 | 100-320 | 160-500 | 1600 | 3400 |

Downloads

Applications

- Injection molding machines

- Hydraulic presses

- Flight simulators

- Fan drives

- Wind turbines

- Elevator/lift drives

- Winch drives

- Marine industry

QXV Internal Gear Pumps

Description

Pumps Low-viscosity fluids

The QXV series has been developed for use with low-viscosity fluids. QXV pumps have proven particularly successful in applications for pumping kerosene, automotive fuels, paraffin, brake fluids and many other low-viscosity fluids. When required, a multi-stage pressure build-up can be employed to achieve high pressures of up to 250 bar with a viscosity close to 1 mm2/s, and with high efficiencies at the same time.

Advantages

- For open circuits up to 250 bar max. working pressure

- For low-viscosity fluids from 0.8 mm2/s to 10 mm2/s

- High temperatures up to 160 °C are possible

- Available in EX-proof versions EX II 3 G T3 and T4

- Can be used with variable-speed drives

Technical Data

| Type | Operating pressure (continuous) up to bar |

Displacement cm³/rev |

Speed max. rpm |

|---|---|---|---|

| QXV2 | 250 | 5-16 | 3600 |

| QXV3 | 250 | 10-32 | 3600 |

| QXV4 | 250 | 20-63 | 3600 |

| QXV5 | 250 | 40-125 | 3000 |

| QXV6 | 250 | 20-63 | 1800 |

| QXV8 | 250 | 160-500 | 1800 |

Applications

- Test equipment for fuel regulators and commercial aircraft

- Test benches for diesel injectors

- Fuel pumps for gas turbines

- Welding systems

- Lubricating oil supply for precision spindle bearings

- Steel works