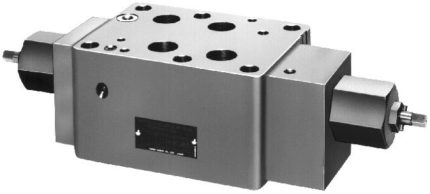

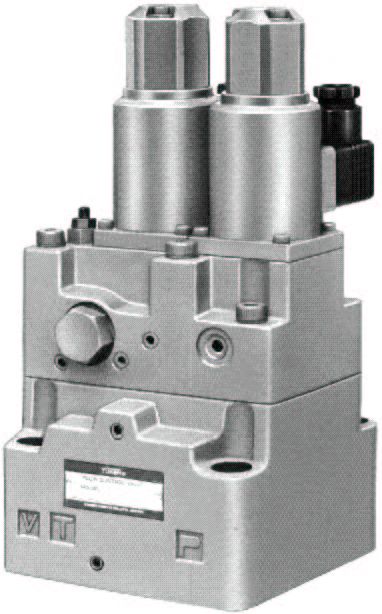

005 Series Modular Valves

YUKEN’s Modular Valves are stack type valves, and require no piping. They not only rationalize system build, but they also meet the technical requirements for a variety of hydraulic systems. Stacking systems is a new era in hydraulics. The valves have standardized mounting surface conforming to ISO 4401 and optimum thickness for each size. Any hydraulic circuits can be easily composed by stacking the valves with mounting bolts. The valves can be used widely for hydraulic systems for various industries such as machine tools, special purpose machines, ships and steel mill equipment.

Features:

1. Installation and mounting space can be minimized.

2. No special skill is required for assembly and any addition or alteration of the hydraulic circuit can be made quickly and easily.

3. Problems such as oil-leaks, vibration and noise which may be caused by piping are minimized, increasing the reliability of the hydraulic system.

4. Maintenance and system check-ups can be easily carried out as they are normally installed in stackable units.

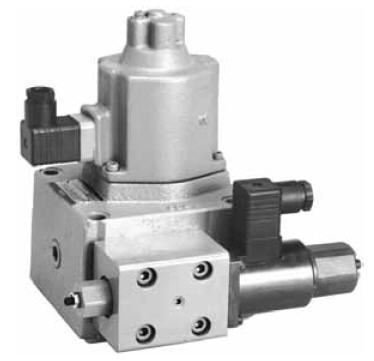

01 Series Modular Valves

YUKEN’s Modular Valves are stack type valves, and require no piping. They not only rationalize system build, but they also meet the technical requirements for a variety of hydraulic systems. Stacking systems is a new era in hydraulics. The valves have standardized mounting surface conforming to ISO 4401 and optimum thickness for each size. Any hydraulic circuits can be easily composed by stacking the valves with mounting bolts. The valves can be used widely for hydraulic systems for various industries such as machine tools, special purpose machines, ships and steel mill equipment.

Features:

1. Installation and mounting space can be minimized.

2. No special skill is required for assembly and any addition or alteration of the hydraulic circuit can be made quickly and easily.

3. Problems such as oil-leaks, vibration and noise which may be caused by piping are minimized, increasing the reliability of the hydraulic system.

4. Maintenance and system check-ups can be easily carried out as they are normally installed in stackable units.

03 Series Modular Valves

YUKEN’s Modular Valves are stack type valves, and require no piping. They not only rationalize system build, but they also meet the technical requirements for a variety of hydraulic systems. Stacking systems is a new era in hydraulics. The valves have standardized mounting surface conforming to ISO 4401 and optimum thickness for each size. Any hydraulic circuits can be easily composed by stacking the valves with mounting bolts. The valves can be used widely for hydraulic systems for various industries such as machine tools, special purpose machines, ships and steel mill equipment.

Features:

1. Installation and mounting space can be minimized.

2. No special skill is required for assembly and any addition or alteration of the hydraulic circuit can be made quickly and easily.

3. Problems such as oil-leaks, vibration and noise which may be caused by piping are minimized, increasing the reliability of the hydraulic system.

4. Maintenance and system check-ups can be easily carried out as they are normally installed in stackable units.

04 Series Modular Valves

Yuken’s 005 to 10 series modular valves come in six sizes and have gained a reputation for their high pressure and flow rate capacities. As part of our product line expansion, we are pleased to announce the release of 04 (1/2) series modular valves. For hydraulic systems with high flow rates, which 03 series valves (maximum flow rate of 70 L/min) are not capable of handling, 06 series modular valves (maximum flow rate of 500 L/min) have been conventionally used. In such cases, the use of 04 series valves for hydraulic systems with flow rates up to 300 L/min will help reduce both cost and size of the systems.

06 Series Modular Valves

Updated design from 30 series to 70 series of the “06” size modular valves. Please confirm dimensions when upgrading from the 30-design to 70-design. See notice of Model Number Change below.

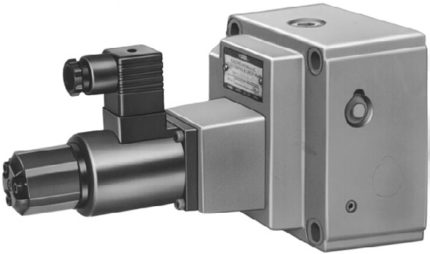

10Ω Series Flow Control and Check Valves (EF(C)G-03/06-51)

Since the preselected flow rate continuously varies in proportion to the current input to the valve, the system flow rate can be remotecontrolled as desired by regulating the current output from the amplifier. Further, since the pressure and temperature compensation functions are provided, the preselected flow rate is not be affected by pressure (load) or temperature (fluid viscosity). This valve is ideal for use where actuator startup, stop, and speed changes are to be implemented without producing a shock. Note that this valve is used in conjunction with the applicable power amplifier.

10Ω Series Flow Control and Check Valves (EF(C)G-03/06-51)

Since the preselected flow rate continuously varies in proportion to the current input to the valve, the system flow rate can be remotecontrolled as desired by regulating the current output from the amplifier. Further, since the pressure and temperature compensation functions are provided, the preselected flow rate is not be affected by pressure (load) or temperature (fluid viscosity). This valve is ideal for use where actuator startup, stop, and speed changes are to be implemented without producing a shock. Note that this valve is used in conjunction with the applicable power amplifier.

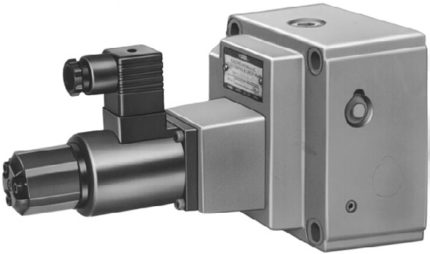

10Ω – 10Ω Series Flow Control and Relief Valves (EFBG-03-125-61/06-250-61/10-500-51)

This flow control and relief valve is an energy-saving valve that supplies the minimum pressure and flow necessary for actuator drive. Since this valve controls the pump pressure by following the load pressure while keeping the differential pressure minimized, it serves as a low power consumption energy-saving, metre-in, controlled flow control valve. Further, since a temperature compensation function is incorporated, this valve provides consistent flow control without respect to the fluid temperature.

10Ω – 10Ω Series Flow Control and Relief Valves (EFBG-03-125-61/06-250-61/10-500-51)

This flow control and relief valve is an energy-saving valve that supplies the minimum pressure and flow necessary for actuator drive. Since this valve controls the pump pressure by following the load pressure while keeping the differential pressure minimized, it serves as a low power consumption energy-saving, metre-in, controlled flow control valve. Further, since a temperature compensation function is incorporated, this valve provides consistent flow control without respect to the fluid temperature.

40Ω Flow Control and Check Valves (EF(C)G-02/03/06/10)

Since the pre-selected flow rate continuously varies in proportion to the current input to the valve, the system flow rate can be remote controlled as desired by regulating the amplifier current output. Further, since pressure and temperature compensation functions are provided, the pre-selected flow rate is not affected by pressure (load) or temperature (fluid viscosity). This valve is ideal for use where actuator startup, stop, and speed changes are to be implemented without producing a shock. Note that this valve is used in conjunction with the applicable power amplifier.

40Ω – 10Ω Series Flow Control and Relief Valves (EFBG-03/06/10-17)

This flow control and relief valve is an energy-saving valve that supplies the minimum pressure and flow necessary for actuator drive. Since this valve controls the pump pressure by following the load pressure while keeping the differential pressure minimized, it serves as a low power consumption energy – saving, metre-in, controlled flow control valve. Further, since a temperature compensation function is incorporated, this valve provides consistent flow control without respect to the fluid temperature.

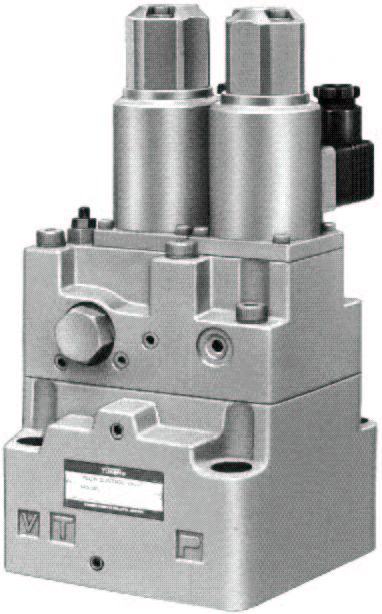

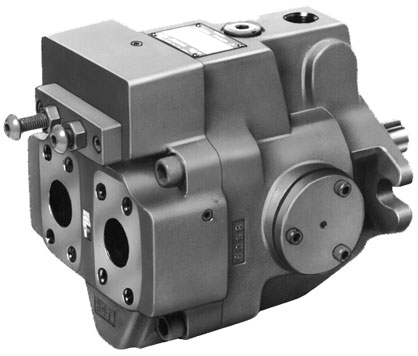

A Series Variable Displacement Piston Pumps

- A variety of control methods are supported

- Ten types of unique control methods are available which integrate amplifiers and sensors. These control types range from standard pressure compensator control to proportional solenoid pressure/flow control.

- Available in a wide range of displacements from 10 to 219 cm3/rev (.610 to 13.36 cu. in. /rev)