Deceleration & Check Valves (Z(C)T-03(06)(10))

These valves are available either with or without an integral check valve which allows free reverse flow. Flow rate through the valve is regulated by the movement of the spool, which is operated by a cam. When the spool is depressed, the flow is decreased in Normally Open type valves and increased in Normally Closed type valves. Their principal use is to control the speed of actuators in machine tools and similar applications.

EH Pilot Relief Valves (EHDG-01)

The valve can be used as a pilot valve of the Proportional Electro- Hydraulic Control Valves. The valve can also be used as a relief valve for the hydraulic system where a small flow rate and continuous pressure control are required.

Feed Control Valves (UCF1(2)G-01(03)(04))

These valves are the combination of flow control valve, a deceleration valve and a check valve and used mainly for controlling rapid traverse and feed cycles machine tools. Switching from rapid traverse to feed is made by a cam operation, and fine feed control is accomplished by dial rotation regardless of pressure and oil temperature variation. Rapid return is free of cam actuation.

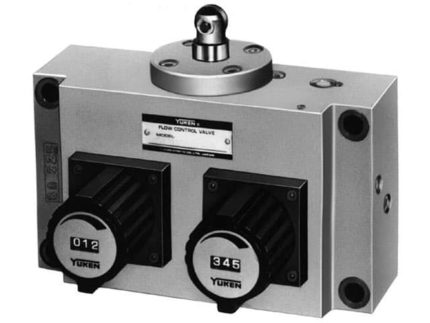

Flow Control & Check (F(C)G)

These valves are pressure and temperature compensating type valves and maintain a constant flow rate independent of change in system pressure (load) and temperature (viscosity of the fluid). They control flow rate of the hydraulic circuit and eventually control speed of the actuator precisely. Valves with an integral check valve allow a controlled flow and reverse free flow. Repeated resetting can be made easily with a digital readout.

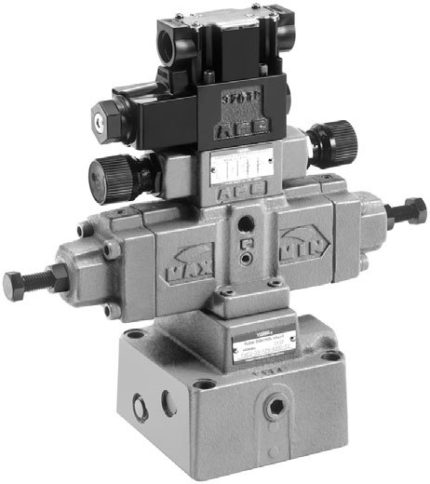

Flow Control and Relief Valves (FBG-03/06/10)

These valves are flow control valves having the functions of metre-in type flow control and pressure control. Inlet pressure is always maintained 0.6 MPa (87 PSI) higher than the load pressure.

In a conventional flow control method, power consumption is wasteful since the pump pressure goes up to the preset system pressure regardless of the load pressure. While, the power saving valves control the pump pressure by maintaining a differential pressure as little as 0.6 MPa (87 PSI) against the load pressure, thereby, the power can be remarkably saved.

Moreover, with the temperature compensator, a stable flow control can be made regardless of oil temperature. Setting and repeat setting of flow can be made easily with an adjustment knob having digital scales.

Needle Valves (GCT GCTR)

Used as stop valves for pressure gauge lines and small-capacity line. Also can be used as restrictors for regulating flow rates in pilot lines.

Pilot Operated Flow Control Valves (FH(C)G)

Flow control of these valves is continuously made by a hydraulically operated pilot piston mechanism which controls opening area of the orifice of the valve. With the use of these valves, shockless operation either in acceleratio or deceleration can be obtained. With the compensator for the pressure and temperature, stable flow control can be obtained regardless of the changes in the pressure (load) and temperature (oil viscosity).

Restrictors (SRT SRG SRCT SRCG)

This valve is used to regulate an actuator speed in a circuit where line pressure is almost steady and small fluctuation of oil flow due to pressure changes is permitted. Integrated check valve allows reversed free flow from outlet to inlet port. Pressure balanced construction provides less effort in adjustment at high pressure.

Throttle Modules

Used as pilot choke valves for solenoid controlled pilot operated directional valves and pilot operated directional valves.