Pressure Monitors (DP SJT)

The pressure monitoring system is for watching hydraulic system pressure and is composed of highly reliable pressure sensor (SJT*-02-10) and easy-to-use digital pressure monitor (DP*-*-*-10). There is no specific model number code for the pressure monitoring system itself, therefore, when ordering, specify the digital pressure monitor and pressure sensor with respective model number code.

Remote pressure indication

Even if the monitor is located away from the unit, remote pressure indication can be obtained by combination with special sensors.

Remote-setting pressure sensors

The pressure sensor can be used as a pressure switch with two contacts: top and bottom. Pressure can be set and checked without using any other pressure gauge, moreover, such pressure setting and pressure check can be made when no pressure is applied in the hydraulic system.

Pressure Reducing & Relieving Valves (RBG)

Pressure reducing and relieving valves are composite pressure control valves having pressure reducing and counterbalancing functions developed for hydraulic balancing circuits.

Pressure Reducing/Pressure Reducing & Check (RT RG RCT RCG)

Pressure reducing valves are used to set the pressure of a hydraulic circuit below that of the main circuit. In addition, operation under remote control is possible by using the remote control port. Pressure reducing and check valves have check valves, which allow a free flow from the secondary side to the primary.

Priority Valve

Description

Priority valves are used to provide a hydraulic function in a load sensing system with a priority flow.In principle, they operate like a 3-way flow control valve that always supplies the actuator that has priority with the required flow rate, and passes the remaining flow to other actuators. In an under-supply situation, the actuators without priority are no longer supplied.

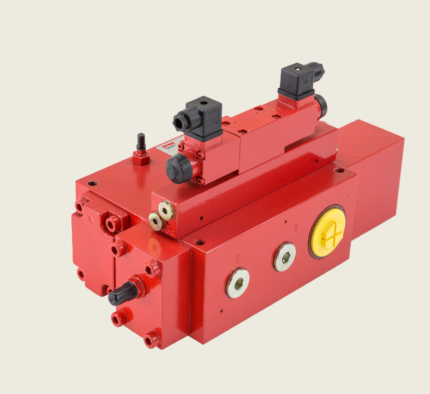

Proportional Directional Valves CV

Description

This range of proportional valves is used to provide load-independent speed control of motors and cylinders.

CV (Compac) means: all valves functions are integrated into one compact block.

Proportional Directional Valves MV

Description

This range of proportional valves is used to provide load-independent speed control of motors and cylinders.

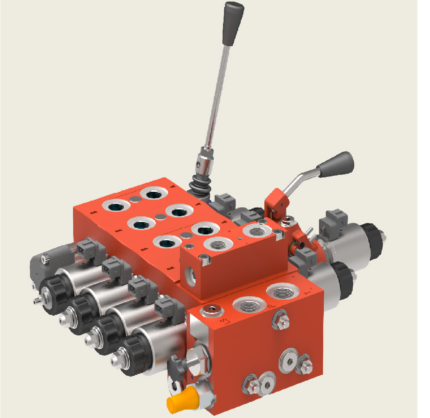

Proportional Directional Valves, Series L.8S

Description

The L.8S valve series covers an actuator flow rate of up to 90 l/min and was developed for mobile applications. The valves are particularly characterized by their robust design and small external dimensions, and they offer a wide variety of additional functions that can be integrated. The L.8S is a flexible modular system whose elements can be combined to form a valve block that complies fully with the requirements of the application. The valve blocks can be configured for fixed-displacement or load-sensing pump systems as well as for systems that can switch between either type of supply.

Proportional Directional Valves, Series LCV

Description

Series LCV proportional directional control valves have been developed for use in tractors and similar applications. The high level of integrated functionality combined with the ability to parametrize the valve characteristics provide the basis for enhanced system solutions. The outstanding dynamics and stiffness of the valve’s stepper-motor operation ensure first-rate control of the actuators. Flexibility within the sections themselves, and supplementary functions in bolt-on plates, open the door to optimized solutions. The fully automated high-volume production guarantees extremely high quality at very attractive terms. Achieve maximum productivity with reduced energy consumption.