CDSC(T)(G) Series Poppet 2-Way

These valves are used for opening/closing the oil path by having the poppet valve operated with an electric signal via solenoid. Because these are of poppet type, the internal leakage is quite small and there is no worry about hydraulic lock.

CIT Series In-Line Check Valves

These valves allow free flow in one direction and prevent flow in the reverse direction. Cracking pressure specified is the pressure required to open the valve and allow free flow.

CPT/CPDT – CPG/CPDG Pilot Controlled Check

These check valves allow flow in one direction and prevent flow in the reverse direction, until operated by pilot pressure to allow free reverse flow. The specified cracking pressure is required to open the valve to allow free flow direction.

CRT – CRG Series Right Angle Check

These valves allow free flow in one direction and prevent flow in the reverse direction. Cracking pressure specified is the pressure required to open the valve and allow free flow.

DCT – DCG Series Cam Operated

These valves may be used to shift the direction of oil flow by depressing the spool by way of a cam.

DHG Hydraulic Pilot

These valves perform a change over of spool by hydraulic pilot and shift the direction of oil flow.

DMT – DMG Series Manually Operated

These valves may be used to manually shift the spool position and change the direction of oil flow.

DRT-DRG Series Mechanically Operated/Rotary Type Directional Valves

Mechanically Operated Directional Valves

These valves are chiefly used to shift the pilot circuit. Rotary Type Directional Valves and Cam Operated Type Directional Valves are available.

Rotary Type Directional Valves

These valves are used to rotate the spool either manually or by way of cam and shift the direction of oil flow. The detented mechanism incorporated in these valves prevents the valve from being changed over by itself due to vibrations or any other shocks.

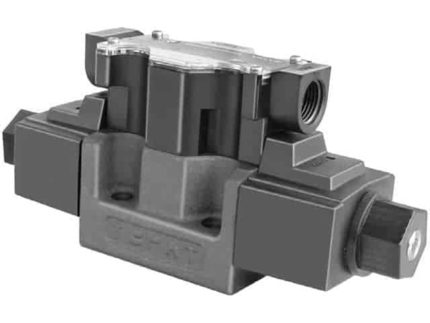

DSG-005 Series Solenoid Operated Directional Valves

These DSG-005 series solenoid directional valves are the products newly developed as a “Mini-series”. Compared with DSG-01 series, the valve are much more compactly manufactured but enjoy a maximum operating pressure of 25 MPa (3630 PSI) and a maximum flow rate of 15 L/min (3.96 U.S.GPM), while contributing further to a space saving requirement. Moreover, using wet armature solenoids, the valves ensure the long life.

DSG-01-70 Series Solenoid Operated Directional Valves

1/8 Solenoid Operated Directional Valves, DSG-01 Series – These are Solenoid Operated Directional Valves of high pressure, high flow and low pressure drop, the features of which can be materialized by employing a powerful wet type solenoid and the rational flow channel design.

DSG-03 Series Solenoid Operated Directional Valves

3/8 Solenoid Operated Directional Valves, DSG-03 Series.

These are epoch-making solenoid operated valves of high pressure, high flow which have been developed incorporating a unique design concept into every part of the valve including the solenoid. With wet type solenoids, these valves ensure the low noise and the long life, moreover, ensure no leakage of oil outside of the valves.

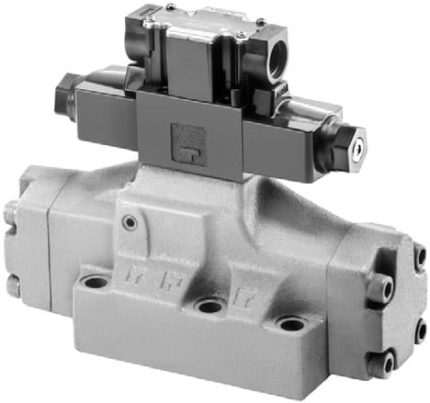

DSHG Pilot Operated Series Solenoid Operated Directional Valves

Solenoid Controlled Pilot Operated Directional Valves.

These valves are composed of a solenoid operated pilot valve and a pilot operated slave valve. When a solenoid is energized the pilot valve directs the flow to move the spool of the slave valve, thus changing the direction of flow in the hydraulic circuit.

DSLG Series Solenoid Poppet Type

These are Solenoid Operated Directional Valves of No Leak Type developed with the aim of responding the demand of the age including energy saving. Because these valves are of no leak type they allow the low viscosity hydraulic fluids to be used as well as the circuit construction which cannot be used by the conventional spool type directional valves because of too much internal leak of pressure oil. The use of the low viscosity hydraulic fluids reduces the pressure loss which can arise from the passage resistance of the hydraulic fluids, leading to the system energy saving.

DSLHG Series Multi-Purpose Type

YUKEN’s Multi Purpose Control Valve s are compound valves composed of the main valve having four poppets, 1/8 Solenoid Operated Directional Valves for pilot and Pilot Selector Valves. This valve is multifunctionalized by having individual poppet had functions such as directional control, flow control or pressure control according to the combination of the main valve and pilot selector valve.

DSLHG Series Multipurpose Valves

The multipurpose control valve that offers regenerative circuits, directional control, flow control, counterbalance and reduced shock features.

DSPC – DSPG Series Shut-Off Solenoid Operated

The shut-off type solenoid operated directional valves are poppet type solenoid operated two-way directional valves developed to meet the needs of this age such as energy and resources saving.

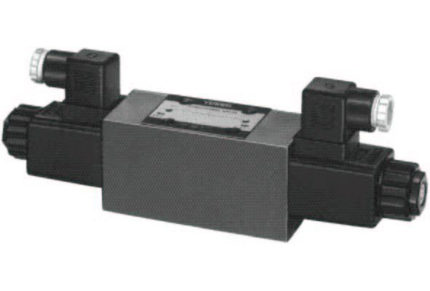

G-DSG Series Shockless Directional Valves

The G-Series Solenoid Operated Directional Valves incorporate electronic circuits o enable adjustment of the spool shifting time. A special spool shape that minimises shock is used, shocks caused by the

actuator starting and stopping, as well as vibration due to oil hammering. The shifting time of conventional Solenoid Operated, Shockless, and Directional Valves is constant and cannot be adjusted. As the shifting time of the G-Series valves can be adjusted, it can be set at an optimal level to minimise shocks to the machine.

Increased Safety – Explosion Proof – Solenoid Controlled Directional Valves

Explosion Proof (Flameproof) Solenoid Operated Directional Valves. For use in Division 1 & 2 locations

Explosion Proof (Increased Safety Type) Solenoid Operated Directional Valves. For use in Division 1 locations

O-Ring Sizes

Data Sheet:

Size of O-Ring | SAE J1926-1 SAE Straight Thread O-Ring Port — (For “950” (N. American) Design Standard).

T-DSG Electronic Relay Incorporated

Electronic Relay Incorporated Solenoid Operated Directional Valves

Drive power source and signal are separate.

The valve is actuated by operating a built-in switch using a very small current signal (about 10 mA) when the solenoid is energized.

A Direct Drive by a programmable controller is now possible.

As the valve can be actuated by a very small current, as we have mentioned, a Direct Drive is possible on the output circuit of the programmable controller or sequence controller.

Simple construction and stable operation.

Since the valve is a direct type, the construction is quite simple. Also the solenoid is the well proven wet armature type, which can withstand contamination. Therefore a stable operation can be obtained.