External Gear Motors, Series APM

Description

The essential components of series APM212 external gear motors are an aluminium alloy body and two gearwheels supported by plain bearings.

The front flange can be the SAE standard, or the British or German OEM patterns.

Particular attention has been focussed on the design of the shaft seal, which is often affected by back-pressures

External Gear Pumps, Series AP

Description

The product range of Bucher Hydraulics includes single pumps 05-100-212-212HP-250HP-312HP (corresponding with the common group denominations: 05-1-2-2.5-3) and several combinations of double pumps, triple pumps, and so on, that can be assembled together according to versions of displacement, flanging, and auxiliary valves.

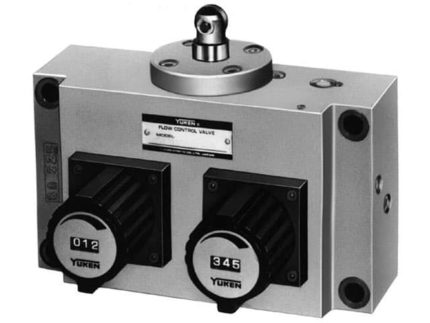

Feed Control Valves (UCF1(2)G-01(03)(04))

These valves are the combination of flow control valve, a deceleration valve and a check valve and used mainly for controlling rapid traverse and feed cycles machine tools. Switching from rapid traverse to feed is made by a cam operation, and fine feed control is accomplished by dial rotation regardless of pressure and oil temperature variation. Rapid return is free of cam actuation.

Flow Control & Check (F(C)G)

These valves are pressure and temperature compensating type valves and maintain a constant flow rate independent of change in system pressure (load) and temperature (viscosity of the fluid). They control flow rate of the hydraulic circuit and eventually control speed of the actuator precisely. Valves with an integral check valve allow a controlled flow and reverse free flow. Repeated resetting can be made easily with a digital readout.

Flow Control and Relief Valves (FBG-03/06/10)

These valves are flow control valves having the functions of metre-in type flow control and pressure control. Inlet pressure is always maintained 0.6 MPa (87 PSI) higher than the load pressure.

In a conventional flow control method, power consumption is wasteful since the pump pressure goes up to the preset system pressure regardless of the load pressure. While, the power saving valves control the pump pressure by maintaining a differential pressure as little as 0.6 MPa (87 PSI) against the load pressure, thereby, the power can be remarkably saved.

Moreover, with the temperature compensator, a stable flow control can be made regardless of oil temperature. Setting and repeat setting of flow can be made easily with an adjustment knob having digital scales.

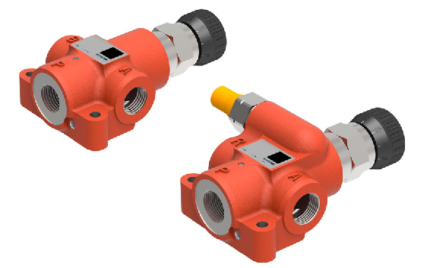

Flow Control Valve MTQA

Description

Series MTQA priority flow control valves provide a constant, pressure-compensated, flow of hydraulic fluid in one direction. They divide an inlet flow into a constant, priority, flow and a surplus flow. The whole inlet flow is protected by an adjustable pressure relief valve. The surplus flow should be returned directly to tank.

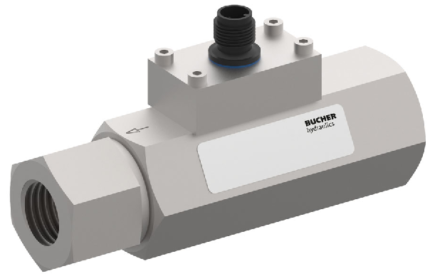

Flow Detector Series FD

Description

The series FD flow detector, nominal size 12, detects a preset flow rate and can be used for various monitoring functions.

Meeting the safety requirements of EN ISO 13849 often requires fitting an upstream valve as a second shut-off route. Its diagnostic information is provided by a downstream pressure transducer. In this way, a safe shut-off is always possible. The one remaining loophole is where a directional valve jams in the operated position, a situation that cannot be detected until another, parallel-connected actuator is operated. This loophole can be closed with the flow detector, which is fitted downstream of the On/Off valve. When the On/Off valve is initially opened, there must be no significant flow. Next the respective directional valve should be operated.

Typically, the flow detector is used for mobile applications in which auxiliary actuators are supplied in parallel from one pressure source. This is required, for example, as a monitoring function for steering pumps in mobile machines.

Flow Divider MTDA (High Precision)

Description

The flow dividers in the MTDA High Accuracy series are bi-directional flow dividers. They divide a flow into 2 part-flows with a accuracy of ± 1.5%, even with different pressures at the actuators. When flow passes through a valve in the opposite direction, the part-flows are combined into one single flow (added).

The dividing and combining functions are independent of the pressures of the two individual flows and of the fluid viscosity.

Flow Divider MTDA (High Pressure)

Description

The flow dividers in the MTDA High Pressure series are bi-directional flow dividers. They divide a flow, the total rate of which may be varied, into a maximum of 2 part-flows. When flow passes through a valve in the opposite direction, the part-flows are combined into one single flow (added). The dividing and combining functions are independent of the pressures of the two individual flows and of the fluid viscosity.

A pressure relief function can be integrated, which can be used for fast end-of-stroke equalization of 2 cylinders. An anti-shock/make-up valve can be integrated, and in this configuration the valve is used as a non-switchable flow divider in vehicles with hydrostatic transmissions.