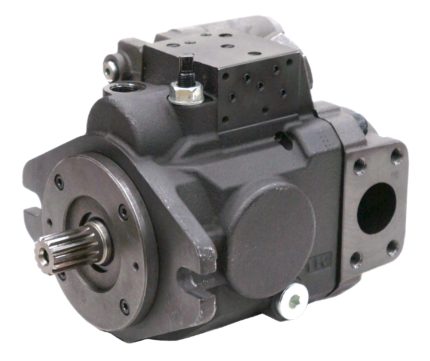

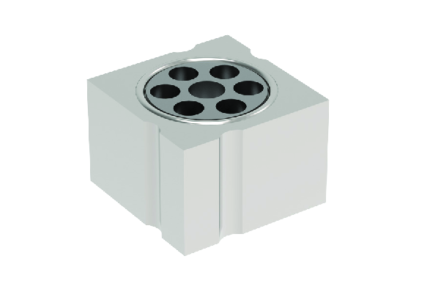

A3HM Series High Pressure Variable Displacement Piston Pumps

- “A3HM“ series piston for open circuit pumps match the requirements of construction machinery and mobile equipment. Drastically compact and lightweight. Suitable for mobile products.

Advantages

- Compact and lightweight compared with conventional pumps.

- Applicable for medium pressure hydraulic systems: Rated Pressure 31.5 MPa and Max. Pressure 35 MPa.

- We offer 6 models in the geometric displacement range from 18.6 to 100.7 cm3/rev. Available for a wide range of applications.

- Through-drive type is employed for standard models. Driven side pumps with displacement volume up to the same displacement as that of the driving pump can be connected. Wide range of maximum flow rates.

A7H Series High Pressure Variable Displacement Piston Pumps

- High Pressure-Large Volume Displacement Adding to current A3H series, 180 and 270 cm3 /rev displacement with rated pres. 35MPa, Max. Pres. 40MPa pumps are now available.

- Optional Through Drive Optional through drive allows an auxiliary or outboard pump (SAE Standard) to be directly mounted.

- Fire-Resistant Fluids Water-Glycols and Polyol Ester Type are applicable under certain condition.

AR Series Variable Displacement Piston Pumps

- AR series variable displacement pump has been developed with the aim of even further quientness in operation, smaller size and lighter mass. Based on Yuken technology and engineering, the “A” series pump has a reputation for its quiet operation and high efficiency.

- Compact and Lightweight

- A compact design and an aluminum body ensures a high power to mass ratio

- Low Noise

ARL1 Series Piston Pumps

- Compact and Lightweight

- Low Noise

- For small displacement from 6.2 to 6.3 cm3 /rev

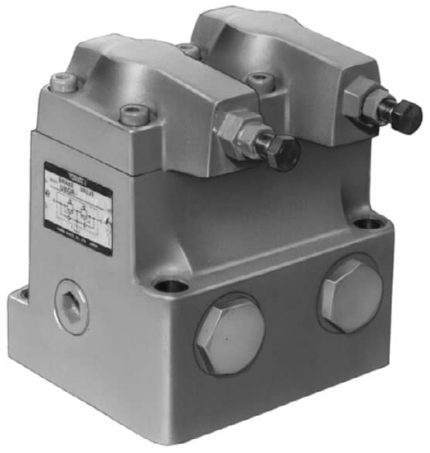

Brake Valves (UBGR)

Brake valves are used on hydraulic cylinders and in brake circuits of hydraulic motors. They can brake with any pressure, permitting smooth stopping.

CDSC(T)(G) Series Poppet 2-Way

These valves are used for opening/closing the oil path by having the poppet valve operated with an electric signal via solenoid. Because these are of poppet type, the internal leakage is quite small and there is no worry about hydraulic lock.

Check Valves DERV

Description

Series DERV pilot-operated check valves lock a cylinder in any rest position.

They are intended for direct mounting in the cylinder.

Check Valves ERV

Description

ERV 8, ERV 8-600:

These pilot-operated check valves are size 8, two stage, high performance screw-in cartridges with an (ERV 8: M30x1.5 / ERV 8-600: M34x1.5) mounting thread. The conical-seat design ensures that the cartridges are leak-tight from B → A. The check function can be overridden by applying a suitable pilot pressure at port X. In the A → B direction, flow can pass freely through the valve (opening pressure = 2.5 bar). These screw-in cartridges are predominantly used in certain mobile and industrial applications to maintain the position of loaded actuators (e.g. outrigger cylinders) after the pump pressure has been disconnected.

Check Valves ERVH

Description

Plate-type, screw-in design

Series ERVH

Pilot-operated check valves prevent any flow in one direction. In the opposite direction, free flow with minimal pressure drop is possible. By applying a defined pilot pressure at X, the checked flow direction is held open as long as the pilot pressure is maintained.

Check Valves for SAE Flanged Connections, Fit Between Port and Flange, Sealing on Both SidesRVSAE 3/6DS

Description

Series RVSAE 3/6DS

Patent No. 38 34 066

These patented combination SAE check valves are centered between the shafts of the four SAE flange bolts. This results in a simple, compact assembly.

Check Valves for SAE Flanged Connections, Fit Between Port and Flange, Sealing on One Side RVSAE 3/6

Description

Series RVSAE 3/6

Patent No. 38 34 066

These patented combination SAE check valves are centered between the shafts of the four SAE flange bolts. This results in a simple, compact assembly.

Check Valves REP…

Description

Series REP… check valves prevent any flow in one direction but the valves can be made to open by applying pressure to port X. In the opposite direction, flow is unrestricted (opening pressure approx. 2 bar).

Check Valves, Size 04 … 25 RVC

Description

Plate-type, push-in design, invertible Series RVC

Check valves prevent any flow in one direction. In the opposite direction, free flow with minimal pressure drop is possible.

Check Valves, Size 04 … 40 RKVC

Description

Ball-type, push-in design, invertible Series RKVC

Check valves prevent any flow in one direction. In the opposite direction, free flow with minimal pressure drop is possible.

Check Valves, Size 04 … 16 RKVG

Description

Ball-type, screw-in design, series RKVG

These check valves prevent any flow against the screw-in direction. In the opposite direction, free flow with minimal pressure drop is possible.

RKVG-KB = Compact, customary cavity type

Check Valves, Size 04 … 25 RVE

Description

Plate-type, screw-in design, series RVE

Check valves prevent any flow in one direction. In the opposite direction, free flow with minimal pressure drop is possible.

Check Valves, Size 04 … 40 RKVE…

Description

Compared with the previous series, the new generation of hydraulic check valves offers up to 50 percent higher flow rate for the same pressure differential. The larger flow rate saves energy and in many cases allows a smaller valve to be used, which in turn has a positive effect on costs and installation space.

The use of high-quality materials, high-precision production and 100 % quality inspection ensure better use, more performance and higher availability of the machine.

For size 04 up to 16 a metal cutting lip on the valve provides a metal-to -metal seal.

For size 25 up to 40 an external O-ring seals the leakage path between the valve and cavity wall.

The variants differ by:

VD = standard flow-optimized variant

VD22 = optimized for reduced pressures up to p = 220 bar

KB = compact design

Check Valves, Size 04 … 40 RVVE

Description

Ball-type, screw-in design, series RVVE

Check valves prevent any flow in one direction. In the opposite direction, free flow with minimal pressure drop is possible.