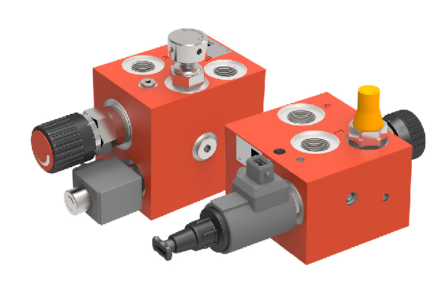

2- and 3-Way Flow Control Valve MTKK / MTKL

Description

Series MTK.. 2/3-way flow control valves provide a constant, pressure-compensated, flow of hydraulic fluid. Any surplus inlet flow can be used elsewhere. The constant flow setting can be fixed or adjustable.

The individual units can be block-mounted; the required number of individual functions can be assembled into one valve block without any interconnecting pipework.

Valve blocks can incorporate both series and parallel circuits.

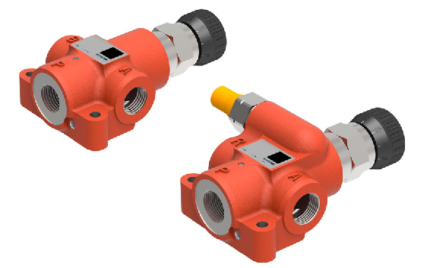

2- and 3-Way Flow Control Valves, Series LVM

Description

Series LVM flow-control valves are used to set the speed of single-acting hydraulic actuators

There are 3 versions of the flow-control valve:

- Load Sensing (LS) pumps without 2-way pressure compensator

- Load Sensing (LS) pumps with 2-way compensator

- Fixed-displacement pumps with integral 3-way pressure compensator

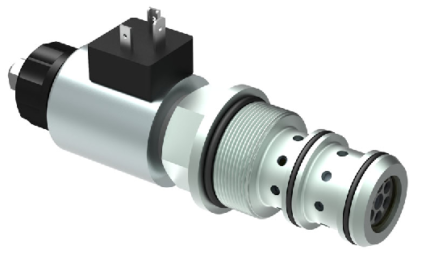

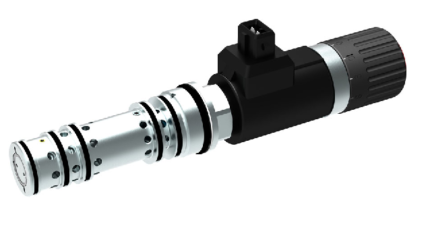

2- and 3-Way Flow Control Valves, Series SRCB

Description

The flow-control valves in this series are used to set the working speed of motors and cylinders, the setting being load-independent, i.e. pressure compensated. The flow rate is set by a slit-type orifice that is adjusted by a proportional solenoid.

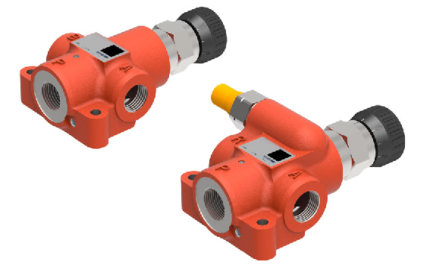

2- and 3-Way Flow Control Valves, Series SRR

Description

Series SRR.. flow-control valves are used to set the working speed of motors and cylinders, the setting being load- independent, i.e. pressure compensated. They divide the inlet flow into a constant-flow portion and a surplus-flow portion.

The surplus flow can be pressurised and can therefore be supplied to a second actuator. This valve can also be used as a 2-way flow control valve by plugging the surplus flow outlet port.

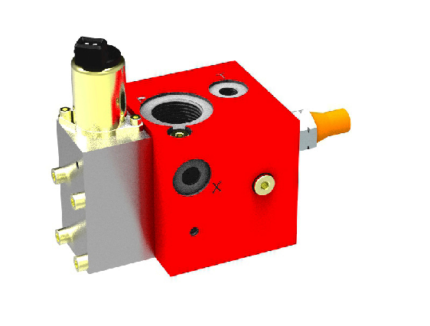

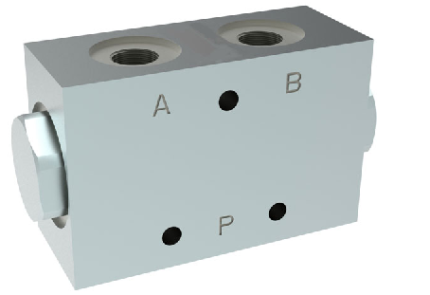

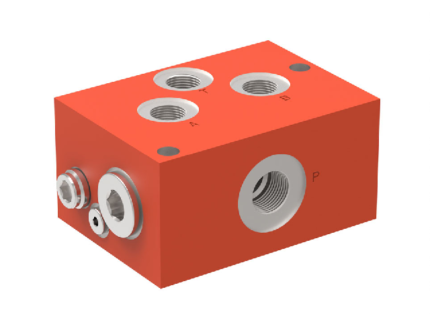

2-way Flow Control Valve MTKE / MTQE

Description

Series MTKE and MTQE flow control valves are monoblock designs with an integral flow divider. They divide the flow entering at port P into a constant flow portion (A) and a surplus flow (T). The constant flow rate is manually adjustable with a hand-knob.

Via a 2-way ON/OFF valve, the entire supply flow can be diverted to tank with virtually no back-pressure. A pressure relief function for the constant flow can be incorporated. The unique advantage of these flow control valves is that the constant flow setting is maintained even after the valve has been switched off.

Flow control valves in the MTKE series can be mechanically switched over for use with Open Centre or Closed Centre systems.

3-Way Flow Control Valve MTKA

Description

Series MTKA priority flow control valves provide a constant, pressure-compensated, flow of hydraulic fluid in one direction. They divide an inlet flow into a constant, priority, flow and a surplus flow. The surplus flow can be pressurised and can therefore be supplied to an additional actuator.

The valve can also be used as a 2-way flow control valve by plugging the surplus flow.

3-Way Flow Control Valves, Series SRCA

Description

The flow-control valves in this series are used to set the working speed of motors and cylinders, the setting being load-independent, i.e. pressure compensated. The flow rate is set by a slit-type orifice that is adjusted by a proportional solenoid.

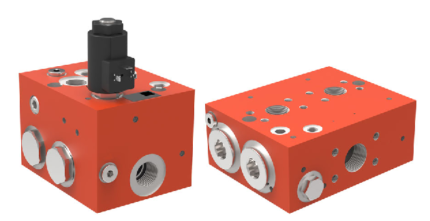

Differential Lock Valve MT..DV Double

Description

Series MT..DV hydraulic differential lock valves are used in open- and closed-loop circuits to drive parallel-connected hydraulic motors in hydrostatically driven vehicles. When the lock valve is switched off, the inlet flow can divide itself among the hydraulic motors in any required ratio, and with minimal pressure losses.

When the lock valve is switched on, the hydraulic motors are compelled to operate at the preset speed ratio. This arrangement prevents any hydraulic wheel motor from spinning in conditions of poor traction. A balancing orifice between the outlets prevents unwanted torque build-up between wheels in these circumstances.

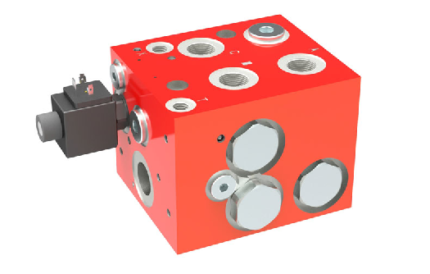

Differential Lock Valve MT..DV Triple

Description

Series MT..DV hydraulic differential lock valves are used in open- and closed-loop circuits to drive parallel-connected hydraulic motors in hydrostatically driven vehicles. When the lock valve is switched off, the inlet flow can divide itself among the hydraulic motors in any required ratio, and with minimal pressure losses.

When the lock valve is switched on, the hydraulic motors are compelled to operate at the preset speed ratio. This arrangement prevents any hydraulic wheel motor from spinning in conditions of poor traction. A balancing orifice between the outlets prevents unwanted torque build-up between wheels in these circumstances.

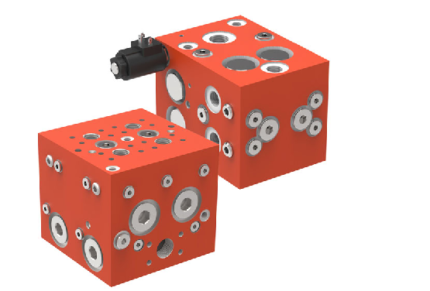

Differential Lock Valve: MT..DVV Quadruple

Description

Series MT..DV hydraulic differential lock valves are used in open- and closed-loop circuits to drive parallel-connected hydraulic motors in hydrostatically driven vehicles. When the lock valve is switched off, the inlet flow can divide itself among the hydraulic motors in any required ratio, and with minimal pressure losses.

When the lock valve is switched on, the hydraulic motors are compelled to operate at the preset speed ratio. This arrangement prevents any hydraulic wheel motor from spinning in conditions of poor traction. A balancing orifice between the outlets prevents unwanted torque build-up between wheels in these circumstances.

Flow Control Valve MTQA

Description

Series MTQA priority flow control valves provide a constant, pressure-compensated, flow of hydraulic fluid in one direction. They divide an inlet flow into a constant, priority, flow and a surplus flow. The whole inlet flow is protected by an adjustable pressure relief valve. The surplus flow should be returned directly to tank.

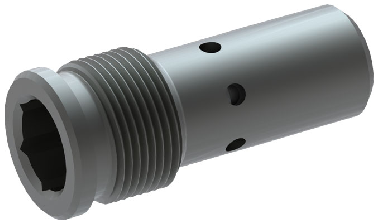

Flow Divider MTDA (High Precision)

Description

The flow dividers in the MTDA High Accuracy series are bi-directional flow dividers. They divide a flow into 2 part-flows with a accuracy of ± 1.5%, even with different pressures at the actuators. When flow passes through a valve in the opposite direction, the part-flows are combined into one single flow (added).

The dividing and combining functions are independent of the pressures of the two individual flows and of the fluid viscosity.

Flow Divider MTDA (High Pressure)

Description

The flow dividers in the MTDA High Pressure series are bi-directional flow dividers. They divide a flow, the total rate of which may be varied, into a maximum of 2 part-flows. When flow passes through a valve in the opposite direction, the part-flows are combined into one single flow (added). The dividing and combining functions are independent of the pressures of the two individual flows and of the fluid viscosity.

A pressure relief function can be integrated, which can be used for fast end-of-stroke equalization of 2 cylinders. An anti-shock/make-up valve can be integrated, and in this configuration the valve is used as a non-switchable flow divider in vehicles with hydrostatic transmissions.

Flow Divider MTDA (Standard)

Description

Series MTDA Standard units are bi-directional flow dividers. They divide a flow, the total rate of which may be varied, into a maximum of 4 part-flows. When flow passes through a valve in the opposite direction, the part-flows are combined into one single flow (added).

The dividing and combining functions are independent of the pressures of the individual flows and of the fluid viscosity.

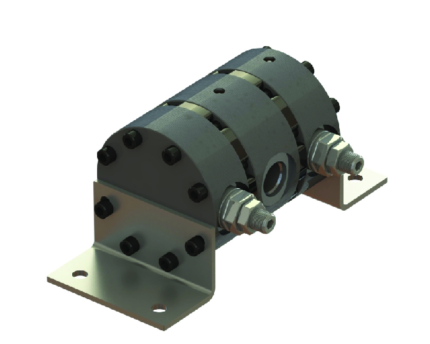

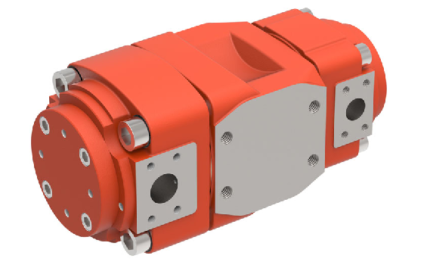

Internal Gear Flow Divider QXT

Description

Series QXT internal flow dividers divide a flow into as many as four portions.

The division ratios are constant and are unaffected by the loads at the actuators.

They can be used, for example, to provide synchronised movement of unequally loaded cylinders. Several hydraulic motors can be driven at the same speed, irrespective of their external loads.