BE/BE12

ISO 5599/1 Valves

– Full range: 1 – 2 – 3 – 4 size

– Commutation system mixed and spool

– High capacity

– Short internal stroke

– No lubrication

– Modular base

– Possibility of mounting different sizes on the same sub-base

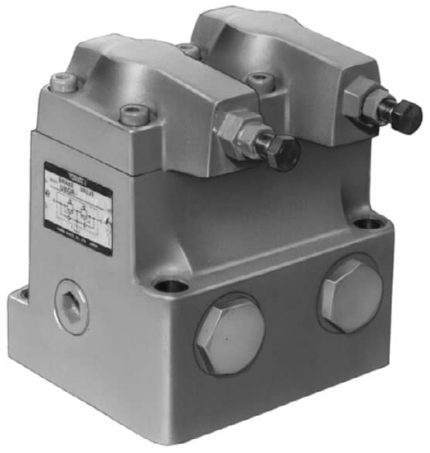

Brake Valves (UBGR)

Brake valves are used on hydraulic cylinders and in brake circuits of hydraulic motors. They can brake with any pressure, permitting smooth stopping.

CDSC(T)(G) Series Poppet 2-Way

These valves are used for opening/closing the oil path by having the poppet valve operated with an electric signal via solenoid. Because these are of poppet type, the internal leakage is quite small and there is no worry about hydraulic lock.

Check Valves DERV

Description

Series DERV pilot-operated check valves lock a cylinder in any rest position.

They are intended for direct mounting in the cylinder.

Check Valves ERV

Description

ERV 8, ERV 8-600:

These pilot-operated check valves are size 8, two stage, high performance screw-in cartridges with an (ERV 8: M30x1.5 / ERV 8-600: M34x1.5) mounting thread. The conical-seat design ensures that the cartridges are leak-tight from B → A. The check function can be overridden by applying a suitable pilot pressure at port X. In the A → B direction, flow can pass freely through the valve (opening pressure = 2.5 bar). These screw-in cartridges are predominantly used in certain mobile and industrial applications to maintain the position of loaded actuators (e.g. outrigger cylinders) after the pump pressure has been disconnected.

Check Valves ERVH

Description

Plate-type, screw-in design

Series ERVH

Pilot-operated check valves prevent any flow in one direction. In the opposite direction, free flow with minimal pressure drop is possible. By applying a defined pilot pressure at X, the checked flow direction is held open as long as the pilot pressure is maintained.

Check Valves for SAE Flanged Connections, Fit Between Port and Flange, Sealing on Both SidesRVSAE 3/6DS

Description

Series RVSAE 3/6DS

Patent No. 38 34 066

These patented combination SAE check valves are centered between the shafts of the four SAE flange bolts. This results in a simple, compact assembly.