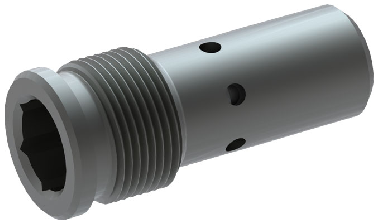

Flow Detector Series FD

Description

The series FD flow detector, nominal size 12, detects a preset flow rate and can be used for various monitoring functions.

Meeting the safety requirements of EN ISO 13849 often requires fitting an upstream valve as a second shut-off route. Its diagnostic information is provided by a downstream pressure transducer. In this way, a safe shut-off is always possible. The one remaining loophole is where a directional valve jams in the operated position, a situation that cannot be detected until another, parallel-connected actuator is operated. This loophole can be closed with the flow detector, which is fitted downstream of the On/Off valve. When the On/Off valve is initially opened, there must be no significant flow. Next the respective directional valve should be operated.

Typically, the flow detector is used for mobile applications in which auxiliary actuators are supplied in parallel from one pressure source. This is required, for example, as a monitoring function for steering pumps in mobile machines.

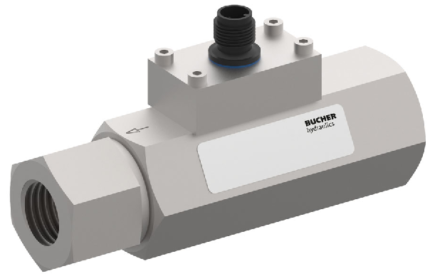

Flow Divider MTDA (High Precision)

Description

The flow dividers in the MTDA High Accuracy series are bi-directional flow dividers. They divide a flow into 2 part-flows with a accuracy of ± 1.5%, even with different pressures at the actuators. When flow passes through a valve in the opposite direction, the part-flows are combined into one single flow (added).

The dividing and combining functions are independent of the pressures of the two individual flows and of the fluid viscosity.

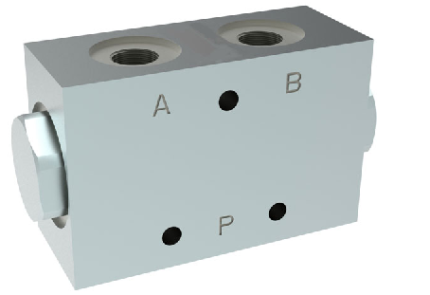

Flow Divider MTDA (High Pressure)

Description

The flow dividers in the MTDA High Pressure series are bi-directional flow dividers. They divide a flow, the total rate of which may be varied, into a maximum of 2 part-flows. When flow passes through a valve in the opposite direction, the part-flows are combined into one single flow (added). The dividing and combining functions are independent of the pressures of the two individual flows and of the fluid viscosity.

A pressure relief function can be integrated, which can be used for fast end-of-stroke equalization of 2 cylinders. An anti-shock/make-up valve can be integrated, and in this configuration the valve is used as a non-switchable flow divider in vehicles with hydrostatic transmissions.

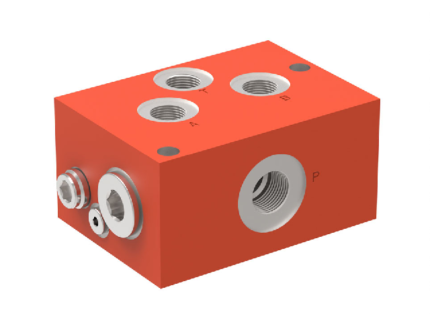

Flow Divider MTDA (Standard)

Description

Series MTDA Standard units are bi-directional flow dividers. They divide a flow, the total rate of which may be varied, into a maximum of 4 part-flows. When flow passes through a valve in the opposite direction, the part-flows are combined into one single flow (added).

The dividing and combining functions are independent of the pressures of the individual flows and of the fluid viscosity.

FMA – LFM

Pmax 7 MPa

Qmax 600 l/min

MATERIALS

Head: Aluminium alloy

Bowl: Cold formed steel

Seals: NBR Nitrile (FKM Fluoroelastomer – on request)

Indicator housing: Brass

PRESSURE

Max working: 0,7 MPa (7 bar)

Collapse, differential for the filter element (ISO 2941): 300 kPa (3 bar)

WORKING TEMPERATURE

From -25° to +110° C

FSC – FSB

Qmax 500 l/min

MATERIALS

Housing: Aluminium alloy

FSC31 & FSC41

Cover & head: Aluminium alloy

Bowl: Polyammide

FSC71 & FSC81

Cover & housing: Aluminium

FSC51 & FSC61

Housing: Steel | Cover: Aluminium

Shut-off valve: Polyammide

Seals: NBR Nitrile

(FKM – on request fluoroelastomer)

Indicator housing: Brass

PRESSURE

Collapse, differential for the filter element (ISO 2941): 100 kPa (1 bar)

WORKING TEMPERATURE

From -25° to +110° C

FSD – MSE

Qmax 700 l/min

MATERIALS

Cover & housing: Anodized aluminium alloy

For 61&62 only

Cover: anodized aluminium alloy | Housing: steel

Bypass valve: Polyammide

Seals: NBR Nitrile

(FKM on request fluoroelastomer)

Indicator housing: Brass

PRESSURE

Collapse, differential for filter element (ISO 2941): 1 MPa (10 bar)

WORKING TEMPERATURE

From -25° to +110° C

FSE – AMF

Qmax 75 l/min

MATERIALS

Head: Aluminium alloy

Spin-on cartridge: Steel

Bypass valve: Polyammide

Seals: NBR Nitrile (FKM on request fluoroelastomer)

Indicator housing: Brass

PRESSURE

Max working: 1,2 MPa (12 bar)

Collapse, differential for filter element (ISO 2941): 400 kPa (4 bar)

BYPASS VALVE

Setting: 30 kPa (0,30 bar) ± 10%

WORKING TEMPERATURE

From -25° to +110° C