Check Valves for SAE Flanged Connections, Fit Between Port and Flange, Sealing on One Side RVSAE 3/6

Description

Series RVSAE 3/6

Patent No. 38 34 066

These patented combination SAE check valves are centered between the shafts of the four SAE flange bolts. This results in a simple, compact assembly.

Check Valves REP…

Description

Series REP… check valves prevent any flow in one direction but the valves can be made to open by applying pressure to port X. In the opposite direction, flow is unrestricted (opening pressure approx. 2 bar).

Check Valves, Size 04 … 25 RVC

Description

Plate-type, push-in design, invertible Series RVC

Check valves prevent any flow in one direction. In the opposite direction, free flow with minimal pressure drop is possible.

Check Valves, Size 04 … 40 RKVC

Description

Ball-type, push-in design, invertible Series RKVC

Check valves prevent any flow in one direction. In the opposite direction, free flow with minimal pressure drop is possible.

Check Valves, Size 04 … 16 RKVG

Description

Ball-type, screw-in design, series RKVG

These check valves prevent any flow against the screw-in direction. In the opposite direction, free flow with minimal pressure drop is possible.

RKVG-KB = Compact, customary cavity type

Check Valves, Size 04 … 25 RVE

Description

Plate-type, screw-in design, series RVE

Check valves prevent any flow in one direction. In the opposite direction, free flow with minimal pressure drop is possible.

Check Valves, Size 04 … 40 RKVE…

Description

Compared with the previous series, the new generation of hydraulic check valves offers up to 50 percent higher flow rate for the same pressure differential. The larger flow rate saves energy and in many cases allows a smaller valve to be used, which in turn has a positive effect on costs and installation space.

The use of high-quality materials, high-precision production and 100 % quality inspection ensure better use, more performance and higher availability of the machine.

For size 04 up to 16 a metal cutting lip on the valve provides a metal-to -metal seal.

For size 25 up to 40 an external O-ring seals the leakage path between the valve and cavity wall.

The variants differ by:

VD = standard flow-optimized variant

VD22 = optimized for reduced pressures up to p = 220 bar

KB = compact design

Check Valves, Size 04 … 40 RVVE

Description

Ball-type, screw-in design, series RVVE

Check valves prevent any flow in one direction. In the opposite direction, free flow with minimal pressure drop is possible.

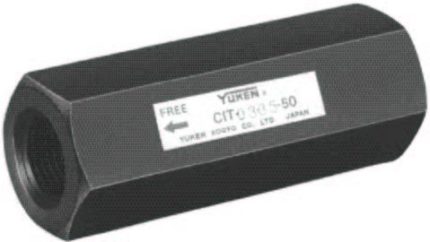

CIT Series In-Line Check Valves

These valves allow free flow in one direction and prevent flow in the reverse direction. Cracking pressure specified is the pressure required to open the valve and allow free flow.

CL/CM

Threaded spool valves UNIVERSAL 3/2 – 5/2 – 5/3

-UNIVERSAL Modular System

– Control: manual, mechanical, pneumatic, electric

-Spool system

-High flow rate, high cycle life, suitable for vacuum application

-Modular sub-bases

CL/CM

-

Threaded spool valves UNIVERSAL 3/2 – 5/2 – 5/3

-UNIVERSAL Modular System

– Control: manual, mechanical, pneumatic, electric

-Spool system

-High flow rate, high cycle life, suitable for vacuum application

-Modular sub-bases

COILS AND CONNECTORS

-

Coils and connectors

UNIVER coils are formed by a self-extinguishing thermoplastic resin envelope and a coil of class H insulated wire that has been impregnated under vacuum. The electrical connection is made with 2-pole female connector (U04 and U05 coils), as well as with DIN43650 (U1-U2-U3-U05 coils) connector and with loose cables.TECHNICAL CATALOGUE