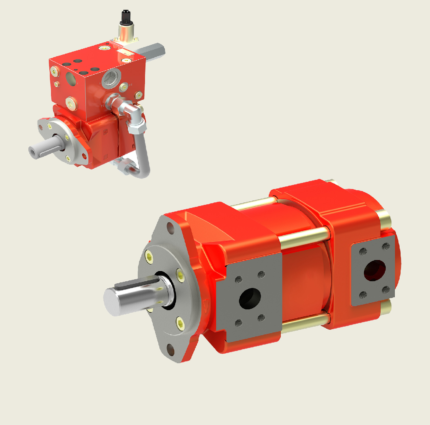

QXM Internal Gear Units

Description

Pump/motor operation in multi-quadrant applications

The QXM series is an extension of the QX pump series and is suitable for operation as both a pump and a motor. Thanks to the completely symmetrical design, these units can be used in multi-quadrant operation and are suitable for a wide range of applications in both industrial and mobile hydraulics. In 4-quadrant operation, the movement of cylinders can be controlled on the one hand, and exploited to recover/save energy on the other. For example, if the unit works as a pump during a lifting process, it can then work as a motor during the lowering process to feed energy back into the system.

Advantages

- Open/closed circuits up to 400 bar max. working pressure

- Low noise level < 75 dB(A)

- Particularly suitable for multi-quadrant operation

- Can be used with all hydraulic fluids

- Can be used with fixed- and variable-speed drives

Technical Data

| Type | Operating pressure (intermittend) up to bar |

Operating pressure (continuous) up to bar |

Displacement cm³/rev |

Speed max. pump rpm |

Speed max. motor rpm |

|---|---|---|---|---|---|

| QXM2 | 400 | 100-320 | 5-16 | 4000 | 4600 |

| QXM3 | 400 | 100-320 | 10-32 | 3200 | 4250 |

| QXM4 | 400 | 100-320 | 20-63 | 2900 | 3900 |

| QXM5 | 400 | 100-320 | 40-125 | 2500 | 3500 |

| QXM6 | 400 | 100-320 | 80-250 | 2250 | 3600 |

| QXM8 | 400 | 100-320 | 160-500 | 1600 | 3400 |

Downloads

Applications

- Injection molding machines

- Hydraulic presses

- Flight simulators

- Fan drives

- Wind turbines

- Elevator/lift drives

- Winch drives

- Marine industry

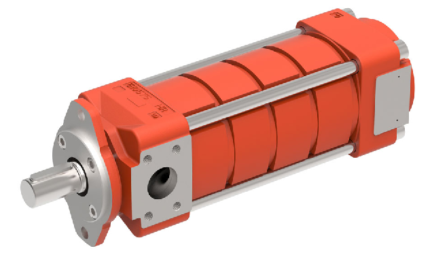

QXV Internal Gear Pumps

Description

Pumps Low-viscosity fluids

The QXV series has been developed for use with low-viscosity fluids. QXV pumps have proven particularly successful in applications for pumping kerosene, automotive fuels, paraffin, brake fluids and many other low-viscosity fluids. When required, a multi-stage pressure build-up can be employed to achieve high pressures of up to 250 bar with a viscosity close to 1 mm2/s, and with high efficiencies at the same time.

Advantages

- For open circuits up to 250 bar max. working pressure

- For low-viscosity fluids from 0.8 mm2/s to 10 mm2/s

- High temperatures up to 160 °C are possible

- Available in EX-proof versions EX II 3 G T3 and T4

- Can be used with variable-speed drives

Technical Data

| Type | Operating pressure (continuous) up to bar |

Displacement cm³/rev |

Speed max. rpm |

|---|---|---|---|

| QXV2 | 250 | 5-16 | 3600 |

| QXV3 | 250 | 10-32 | 3600 |

| QXV4 | 250 | 20-63 | 3600 |

| QXV5 | 250 | 40-125 | 3000 |

| QXV6 | 250 | 20-63 | 1800 |

| QXV8 | 250 | 160-500 | 1800 |

Applications

- Test equipment for fuel regulators and commercial aircraft

- Test benches for diesel injectors

- Fuel pumps for gas turbines

- Welding systems

- Lubricating oil supply for precision spindle bearings

- Steel works

Relief Logic Valves (LB)

These relief logic valves are used to protect pumps and control valves from excessive pressure and control the pressures of their hydraulic lines at constant levels. With the help of vent lines, they are also capable of remote and unload control.

Remote Control Relief Valves (DT-01 DG-01)

This valve is used as a remote control valve for pilot operated type pressure control valves.

Restrictors (SRT SRG SRCT SRCG)

This valve is used to regulate an actuator speed in a circuit where line pressure is almost steady and small fluctuation of oil flow due to pressure changes is permitted. Integrated check valve allows reversed free flow from outlet to inlet port. Pressure balanced construction provides less effort in adjustment at high pressure.

Seat Valves, SVH04

Description

These low-weight (aluminium) seat valve blocks are used to control single- or double acting cylinders. They are applied where high levels of leaktightness are required. The design uses a solenoid operated, direct acting, 2/2 bi-directional seat valve. They close the flow path to or from hydraulic actuators with virtually zero leakage.